In the construction industry, selecting the right materials is crucial. Galvalume Steel Coil has gained popularity for its excellent properties. According to recent industry reports, Galvalume offers superior corrosion resistance compared to traditional galvanized steel. This is due to its unique aluminum-zinc coating, which extends the lifespan of structures. In fact, many contractors report a longer lifespan for roofs made from Galvalume compared to those using standard steel.

However, using Galvalume Steel Coil effectively requires knowledge. Understanding proper installation techniques is vital to maximize its benefits. Many builders overlook the importance of detail, such as ensuring proper edge sealing. This can lead to premature rust, negating its advantages. Additionally, it’s important to consider environmental factors in your area. The local climate can significantly impact how Galvalume performs.

The market is growing, but challenges remain. Certain applications may require additional coatings for enhanced protection. This could increase costs and complicate projects. As we explore how to use Galvalume Steel Coil in your construction projects, these considerations will be critical. Balancing cost, longevity, and style is essential for successful designs.

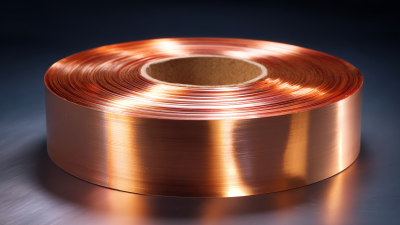

Galvalume steel coil is a popular choice in modern construction. It features a unique blend of aluminum and zinc, providing excellent corrosion resistance. This makes it ideal for various applications, particularly in roofing and siding. The surface of Galvalume is coated, which offers additional protection against harsh weather conditions. This durability is essential for long-lasting structures.

Beyond its resilience, Galvalume steel has a lightweight quality. This can lead to easier handling and installation. Contractors often appreciate how it can reduce overall project time. The material can also be aesthetically pleasing, complementing different architectural styles. However, not all projects may benefit equally from Galvalume. It's crucial to assess the specific environmental conditions you'll encounter.

Installation methods can vary, and improper techniques may lead to issues. Proper training for installers can mitigate potential pitfalls. Additionally, understanding the unique properties of Galvalume is vital. Its expansion and contraction with temperature changes can create challenges. A thoughtful approach to design can avoid future complications. Engaging with experienced professionals can enhance the quality of your project.

This chart illustrates the distribution of Galvalume steel coil usage across various construction sectors in 2026. The data reveals that commercial use dominates, followed by residential and industrial applications, while infrastructure projects account for a smaller percentage.

Galvalume steel coil is increasingly popular in construction due to its unique properties. It combines the benefits of zinc and aluminum, offering exceptional corrosion resistance. This makes it suitable for various structural applications, especially in challenging environments. The reflective surface also helps in reducing heat absorption, contributing to energy efficiency.

When using Galvalume, be aware of key factors. Ensure proper handling during installation. The surface can be sensitive to scratches, which might lead to corrosion later. Always check for any visible damage before you start. Avoid exposure to harsh chemicals that might deteriorate its protective layer.

**Tips:** Proper insulation can enhance the longevity of Galvalume structures. Regular maintenance is essential but sometimes overlooked. Keep an eye on the surrounding environment; it affects the material's lifespan. Despite its durability, proactive care will prevent future issues.

When selecting Galvalume steel coil for construction projects, understanding your needs is crucial. Galvalume offers superior corrosion resistance due to its zinc-aluminum alloy coating. This makes it ideal for roofing and siding applications. According to a recent industry report, projects utilizing Galvalume have shown a 30% longer lifespan compared to traditional galvanized steel. This statistic is significant for those looking to minimize long-term maintenance costs.

Choosing the right thickness is vital. Galvalume coils come in varying gauges. Thicker options provide more durability but can be heavier and more challenging to handle. A study indicated that a gauge of 24 is ideal for roofing in most climates. However, lighter gauges can suffice for interior applications. Always check local building codes; they may dictate the minimum requirements.

Pay attention to the finish as well. A smooth finish may look appealing but can be prone to scratches. On the other hand, a textured surface might hide imperfections better. Projects can benefit from a deeper understanding of their specific environment. For instance, areas with high humidity might require special coatings to maximize the coils' lifespan. Balancing aesthetics and functionality often requires careful thought and perhaps a few adjustments during the selection process.

When using Galvalume steel coils in construction, installation techniques play a crucial role in achieving durability and aesthetic appeal. This material has gained popularity, with a reported 30% of the building industry opting for Galvalume due to its corrosion resistance and longevity. However, careful handling and installation are essential. Workers must be trained to align the coils properly and avoid warping.

One common technique is the use of seam locking, particularly in roofing projects. Proper seam sealing can reduce water ingress significantly. Studies show that buildings that employ efficient seam techniques can see up to a 25% reduction in potential leak issues. While the benefits are clear, installers must be cautious about temperature changes during installation; improper handling in extreme conditions can lead to poor adhesion.

Moreover, the cutting process should be managed wisely. When cutting Galvalume, the exposed edges must be treated promptly to prevent rust. Regular inspections should be incorporated into the project timeline. It's imperative to schedule these checks to ensure every part maintains its integrity. Even with high-quality materials, neglecting these small details can lead to larger problems later on.

Galvalume steel is a popular choice for construction due to its durability and resistance to corrosion. To ensure these structures last, proper maintenance is essential. Regular inspections can catch potential issues early. Look for signs of rust or surface damage, as these can compromise integrity over time.

One key aspect of care is keeping the surface clean. Dirt and debris can trap moisture, leading to corrosion. A simple wash with water and mild soap can do wonders. If you see any scratches, address them promptly. A touch-up with paint can help maintain protection.

Remember, even with the best materials, neglect can lead to problems. Check gutters and drainage systems regularly. Standing water can erode the metal. By being proactive, you can extend the life of your Galvalume steel structures considerably.