In the world of manufacturing, Metal Coils play a pivotal role. They are essential in various industries, including automotive, construction, and electronics. According to a recent report by the Metal Technologies Association, the demand for Metal Coils has increased by over 15% in the last two years. This growth highlights their versatility and importance in modern production.

Identifying different types of Metal Coils can be challenging. There are numerous materials and finishes available. Each type serves distinct purposes, from structural applications to aesthetic enhancements. Industry studies suggest that choosing the right coil can improve efficiency and reduce costs in projects.

However, many projects fail due to poor selection of Metal Coils. This can lead to delays and increased expenses. Awareness of different specifications and applications is crucial for success. Understanding the variety of options helps to avoid common mistakes in metal project planning. Observations show that a well-informed approach can significantly impact project outcomes.

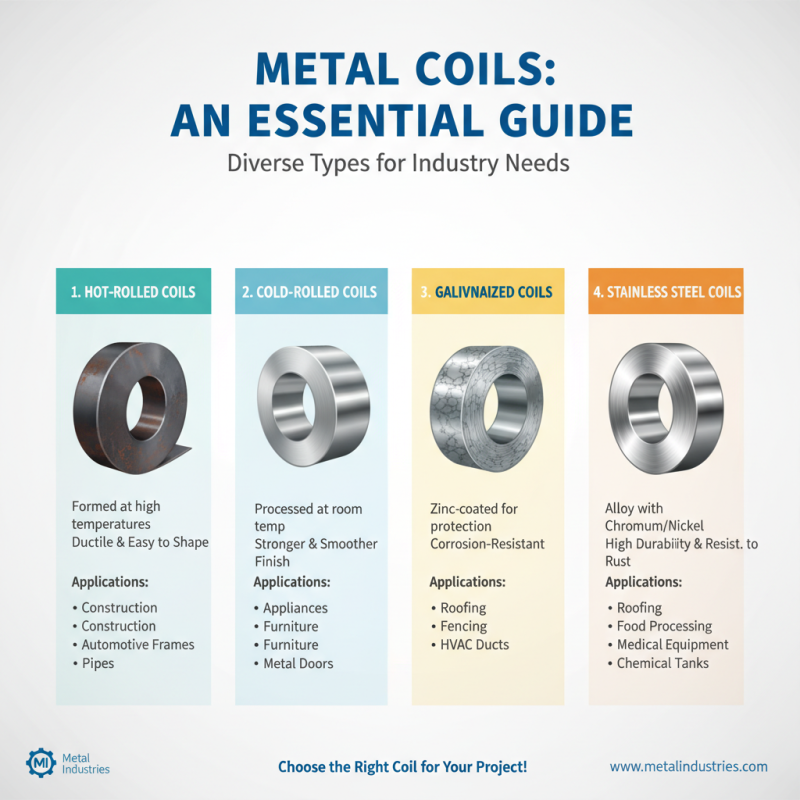

Metal coils are essential in various industries. They come in different types, each with unique properties. Understanding these types helps in selecting the right one for your project.

Steel coils are popular due to their strength and versatility. They can be coated to improve resistance to corrosion. Aluminum coils are lightweight and often used in manufacturing. Their malleability allows for easy shaping. Copper coils, known for their conductivity, are ideal for electrical applications. Each type can suit different needs in construction, automotive, and electronics.

When working with metal coils, choose wisely based on weight, strength, and intended use. Sometimes, it’s hard to determine the right choice without proper testing. A visual inspection may not reveal underlying issues. Misjudging a coil's properties can lead to project delays. Always consider revisiting your selection process to enhance your project outcomes.

When working on metal projects, understanding the different types of metal coils is essential. Metal coils can vary significantly in terms of characteristics and applications. For example, stainless steel coils are resistant to rust and corrosion. According to recent industry reports, they are often preferred in environments like kitchens and medical facilities.

Aluminum coils are lightweight and malleable. They can be easily shaped into various products. Their corrosion resistance makes them ideal for outdoor applications. Recent data shows that aluminum use in construction has increased by over 20% in the past decade. This trend highlights the significance of choosing the right coil for specific applications.

**Tip:** Always consider the environment in which your metal coil will be used. Corrosive elements can degrade certain materials faster.

Copper coils are known for their excellent conductivity. They are commonly utilized in electrical wiring and refrigeration. However, they tend to be more expensive than other types. Balancing cost and functionality is important since every project has budget constraints.

**Tip:** Evaluate the long-term durability of the coil. Cheaper options may lead to higher replacement costs. Find a balance that extends the lifespan of your project.

When working with metal coils, understanding their applications is critical. Different types of metal coils have unique properties that make them suitable for various projects. For instance, stainless steel coils are frequently used in kitchen equipment and medical devices due to their resistance to corrosion and easy cleaning.

Aluminum coils, on the other hand, are lightweight and widely employed in the construction industry. They are often seen in roofing materials and siding because of their durability and aesthetic appeal.

Copper coils are ideal for plumbing and electrical applications. Their excellent conductivity contributes significantly to efficient heat transfer and electrical performance.

Here are a few tips: Always consider the environment when choosing coil types. Will they face harsh conditions? Additionally, measure your project space carefully. A coil too large or small can affect functionality. Finally, assess the long-term needs. Sometimes, cheaper options may lead to more frequent replacements. Reflect on the trade-offs carefully.

Assessing the quality of metal coils is crucial for any project. Start by examining the surface. A smooth finish often indicates better quality. Look for signs of rust or blemishes. These imperfections can weaken the material.

Next, check the coil's dimensions. Accurate thickness and width are essential for your specifications. Use a caliper for precision. Also, consider the coil's weight. Heavier coils can suggest thicker gauges, which might be what you need.

Material composition is another factor to evaluate. Research the alloy types and their properties. Different metals handle stress differently. Sometimes, the right choice may not be obvious. Testing small samples can help you understand how they perform. One mistake can lead to a project setback.

Always reflect on your assessments to improve your next approach.

When selecting the right metal coil for your project, consider the material's properties. Most commonly used materials include steel, aluminum, and copper. Each has distinct characteristics. For instance, aluminum coils are lightweight and resistant to corrosion. Steel coils, on the other hand, are strong and durable, making them ideal for structural applications. According to industry reports, around 45% of metal coil demand comes from the automotive sector, emphasizing steel's predominance.

Understanding the specifications is crucial. Thickness, width, and length all impact usability. Coils can range from 0.004 to 0.500 inches in thickness. The width can be as narrow as 1 inch or go up to 60 inches. Such variations can affect handling and bending during fabrication. Incorrectly chosen dimensions may lead to wastage. Surveys indicate that about 30% of projects encounter delays due to material miscalculations.

Another consideration is surface finish. Metal coils can have various coatings, influencing appearance and functionality. A smooth finish may befit appliances, while a textured finish might enhance grip in automotive parts. It’s not uncommon for fabricators to overlook these details. They might assume that all finishes perform equally, which can lead to issues later on. Remember, selecting the right metal coil requires diligence and careful consideration.

| Type of Metal Coil | Material | Thickness (mm) | Width (mm) | Common Applications |

|---|---|---|---|---|

| Steel Coil | Carbon Steel | 1.5 | 1250 | Automotive parts, Construction |

| Aluminum Coil | Aluminum Alloy | 0.8 | 1000 | Aerospace, Medical equipment |

| Copper Coil | Copper | 1.0 | 600 | Electronics, Plumbing |

| Stainless Steel Coil | Stainless Steel | 1.2 | 1500 | Food processing, Chemical containers |

| Galvanized Coil | Steel with Zinc Coating | 0.5 | 1250 | Roofing, HVAC systems |