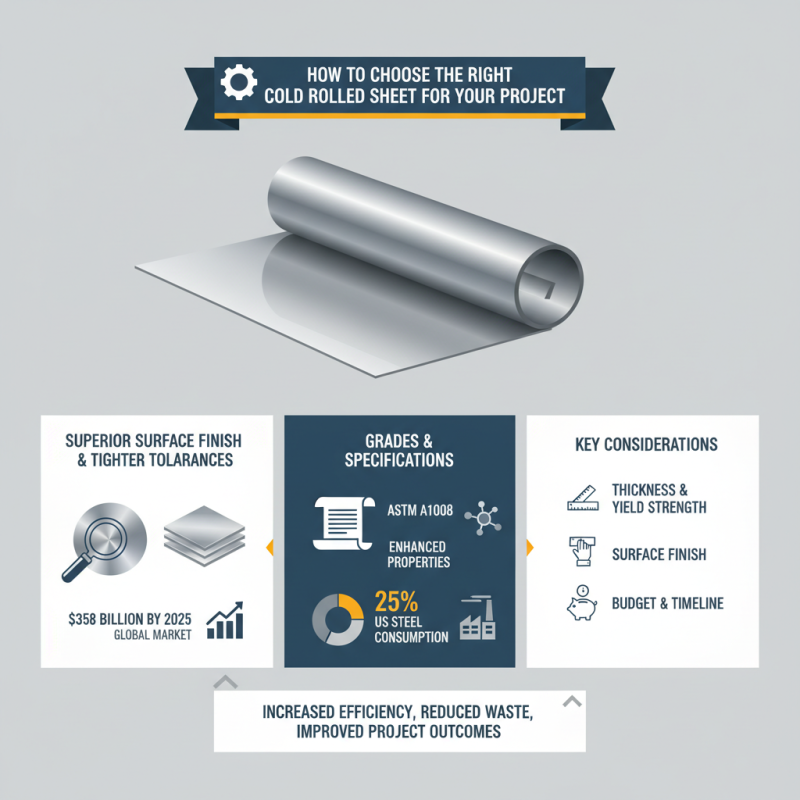

Choosing the right cold rolled sheet for your project is crucial for ensuring structural integrity and achieving the desired aesthetic. Cold rolled sheets, manufactured through a process that involves rolling steel at lower temperatures, offer superior surface finish and tighter tolerances compared to hot rolled steel. According to industry reports, the global cold rolled steel market is projected to reach around $358 billion by 2025, indicating a robust demand across various sectors, including automotive, construction, and appliances.

As you embark on your project, understanding the different grades and specifications of cold rolled sheets becomes essential. For example, ASTM A1008 is a common standard that many manufacturers adhere to, yielding sheets with enhanced mechanical properties and formability. Reports from the Steel Manufacturers Association highlight that cold rolled steel accounts for approximately 25% of total steel consumption in the United States, reinforcing its significance in construction and manufacturing domains.

By carefully considering factors such as thickness, yield strength, and surface finish, you can ensure that you select the right cold rolled sheet that not only meets the technical requirements but also aligns with the project’s budget and timeline. Making an informed decision at this stage can lead to increased efficiency, reduced waste, and improved overall project outcomes.

Cold rolled sheets are essential components in various industries due to their versatility and exceptional properties. They undergo a manufacturing process that enhances their surface finish and dimensional accuracy, making them suitable for a broad range of applications. These sheets are commonly utilized in automotive manufacturing, construction, and appliance production, where strength and formability are key requirements. Their smooth texture and excellent mechanical properties make them a preferred choice for fabricators who need to ensure high-quality results in their projects.

When selecting the right cold rolled sheet for your specific application, it's important to consider factors such as thickness, width, and material grade. Different projects require different specifications, and understanding these needs can greatly affect the final outcome. For instance, heavier applications may demand thicker sheets for added strength, while projects focused on delicate components may benefit from thinner, lighter materials.

Tips: Always consult with suppliers about the chemical composition of the sheets to ensure they meet your project’s requirements. Additionally, considering the potential for galvanization can help enhance corrosion resistance, making it ideal for outdoor applications. Understanding the intended use and environmental factors will guide you toward making a well-informed decision that enhances the longevity and performance of your product.

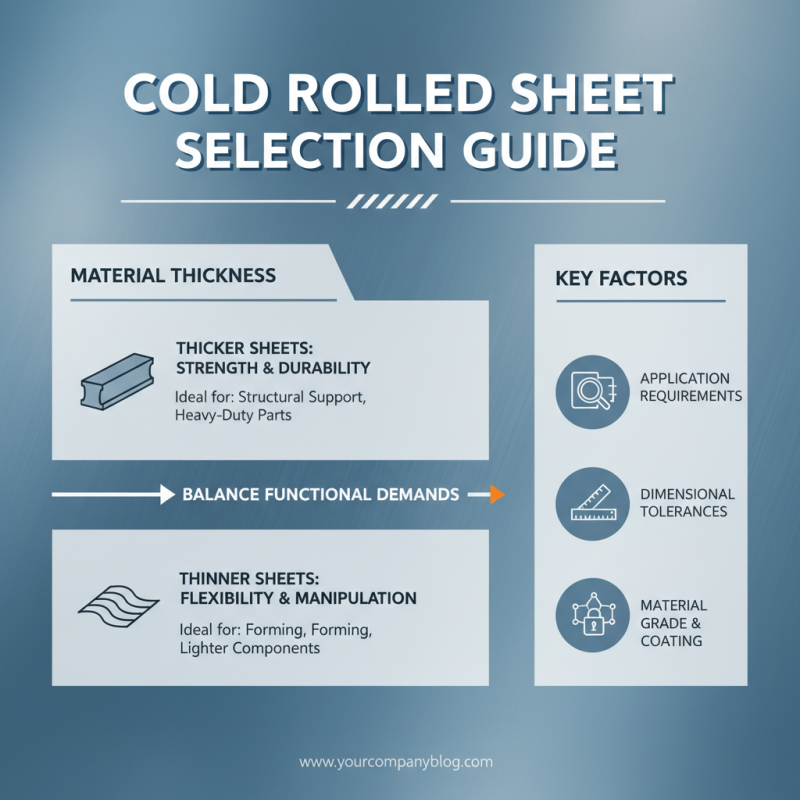

When selecting cold rolled sheets for your project, several factors are critical to ensure you choose the appropriate material for your specific requirements. First, consider the material thickness; thicker sheets typically offer increased strength and durability, which may be crucial depending on the application. Conversely, thinner sheets can be beneficial for projects requiring flexibility and ease of manipulation. It’s important to assess the balance between thickness and the functional demands of your project.

Another vital factor is the surface finish of the cold rolled sheet. Different finishes can affect the sheet's appearance and performance characteristics. For instance, smooth finishes may be preferable for aesthetic applications or where paint adhesion is essential, while textured surfaces can provide added grip or adhere better to certain coatings. Additionally, evaluate the mechanical properties such as yield strength and tensile strength, which can impact how the sheet performs under stress. Understanding how these properties align with your project's requirements will help you make a more informed decision.

When selecting the right cold rolled sheet for a specific project, it's crucial to compare the various grades and thicknesses available in the market. Cold rolled steel is known for its superior surface finish and tighter tolerances compared to hot rolled steel, making it a preferred choice for many applications. According to a recent report by the American Iron and Steel Institute, cold rolled sheets are available in several grades, including commercial steel (CS), drawing steel (DS), and special grades, each of which has distinct mechanical properties that cater to different requirements in manufacturing and construction.

The thickness of cold rolled sheets can significantly influence their performance in applications. Typically, these sheets range from 0.15 mm to over 6 mm, with thinner sheets often used for automotive components and appliances, while thicker sheets are suitable for structural components and machinery frameworks. The choice of thickness should align with the structural demands and weight considerations of the project. Industry data suggests that for structural applications, a minimum thickness of 2 mm is advisable to ensure adequate strength and durability under load. Understanding the nuances of each grade and thickness will empower engineers and project managers to make informed decisions that optimize both performance and cost-effectiveness in their projects.

When selecting a cold rolled sheet for your project, understanding the different surface finishes available is crucial. Surface finish not only affects the aesthetic appeal of the material but also influences its performance in various applications. Common surface finishes include matte, polished, and textured options, each with distinct characteristics that can either enhance or detract from the functionality of the sheet. For example, a polished finish may be preferable for applications that require a sleek appearance, while a textured finish can provide improved grip and reduce the visibility of fingerprints.

Tips for selection: Assess the environment in which the sheet will be used. If the application involves exposure to harsh conditions or potential wear, a more durable finish might be required. In contrast, for decorative purposes, a high-gloss finish may be more suitable. Additionally, consider how the surface finish will interact with other materials in your project—some finishes may be more prone to scratching or tarnishing when paired with specific substances.

Another important factor to keep in mind is how the surface finish may affect the processing methods you intend to use. Certain finishes can impact weldability, paint adhesion, or machining capabilities, which are essential considerations during the design phase. Ensuring that the selected cold rolled sheet aligns with your project's requirements will lead to better outcomes and increased overall efficiency.

When selecting the right cold rolled sheet for a project, evaluating the balance between cost and performance is crucial. According to a 2021 report from the Steel Manufacturers Association, the price of cold rolled steel sheets can vary significantly based on grade and finish, with average prices ranging from $800 to $1,200 per ton. Understanding the specific requirements of your project can help you decide whether to invest in higher-grade materials that offer superior performance or to opt for more economical options that fulfill basic needs.

Performance metrics such as yield strength, tensile strength, and surface quality should be considered in relation to cost. For instance, cold rolled sheets can exhibit yield strengths ranging from 250 MPa to over 600 MPa, indicating varying capabilities for withstanding stress. Projects involving structural components may benefit from higher-grade sheets, which often come at a premium but can provide long-term savings by reducing the likelihood of failure and the associated costs of maintenance or replacement. In contrast, if the project demands less stringent performance standards, selecting a lower-grade cold rolled sheet can result in significant cost savings without compromising the overall integrity of the final product material.

Ultimately, a thorough analysis of your project's specific needs versus material costs will ensure that you choose the rightcold rolled sheet that meets both performance requirements and budget constraints.