Choosing the right galvanized pipe for your project can be challenging. Galvanized pipes are popular in construction and plumbing. They are durable and resistant to rust, making them a preferred choice for many. However, not all galvanized pipes are created equal.

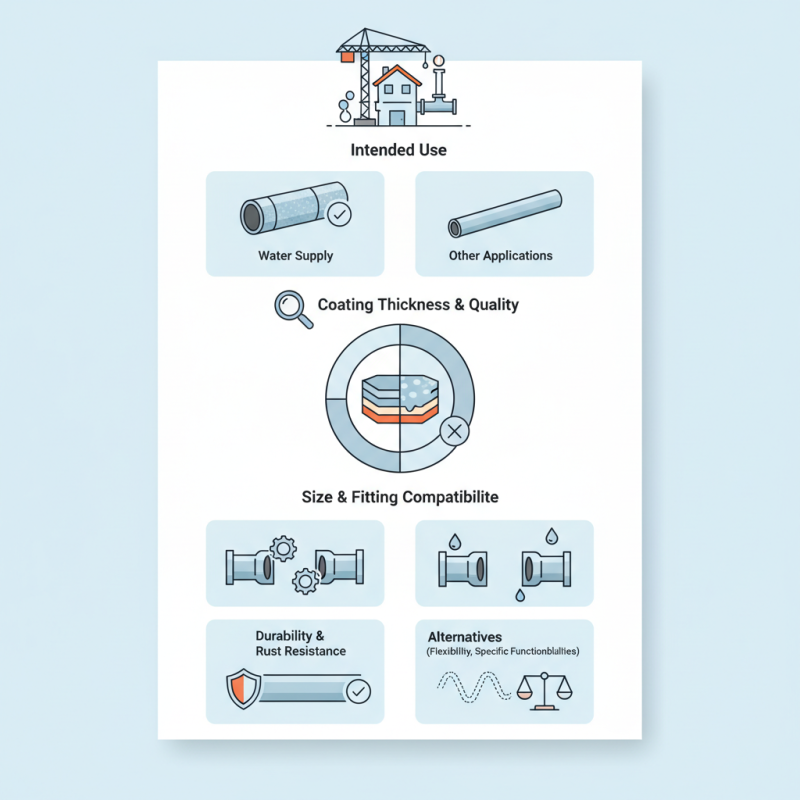

When selecting a galvanized pipe, consider its intended use. Different projects require different specifications. For instance, a pipe meant for water supply must meet specific standards. Make sure to check the pipe's coating thickness and quality. This can significantly affect its longevity and performance.

One common mistake is overlooking size and fitting compatibility. Using the wrong size can lead to leaks or blockages. Reflect on your project needs before making a decision. Gathering all necessary information is key. Galvanized pipes may not be the best option for every situation. Consider alternatives if your project requires higher flexibility or specific functionalities.

Choosing the right galvanized pipe for your project hinges on various important factors. First, consider the pipe’s purpose. Is it for plumbing, construction, or fencing? Each application demands different specifications. The thickness and diameter of the pipe also impact its strength and flow capacity. Ensure your choice aligns with the demands of your project.

Another vital consideration is the environmental conditions. Will the pipe be exposed to moisture or harsh chemicals? Corrosion resistance varies by coating. Additionally, installation requirements can be tricky. Some may require threading or fittings, while others do not. It’s crucial to ascertain compatibility with your fittings.

**Tips:** Always check local building codes. They may dictate specific materials and sizes. It’s also wise to consult with professionals if you are unsure. Sometimes, choosing a less popular size can lead to availability issues. Keep this in mind; flexibility can save time and money. Make sure to measure accurately; discrepancies could lead to project delays.

| Factor | Description | Recommended Use |

|---|---|---|

| Pipe Diameter | The internal diameter of the galvanized pipe, impacting flow rate. | Ideal for plumbing and drainage systems. |

| Wall Thickness | Thickness of the pipe walls, affecting strength and longevity. | Recommended for high-pressure applications. |

| Length | Standard lengths available for convenience in installation. | Useful for both residential and commercial projects. |

| Coating Quality | The quality of the galvanization process, affecting corrosion resistance. | Best for outdoor and humid environments. |

| Temperature Resistance | Ability of the pipe to withstand different temperature ranges. | Suitable for hot water systems or heating applications. |

| Connecting Methods | Types of fittings compatible with the pipe for installation. | Essential for proper assembly and durability. |

When selecting the right galvanized pipe, understanding the types available in the market is crucial. There are two main categories:

black and

gray galvanized pipes.

Black pipes are typically used for gas and less prone to corrosion. Meanwhile, gray galvanized pipes offer better resistance to rust and are often used for water transport.

Another noteworthy type is the schedule 40 pipe. This pipe is thicker and more durable, suitable for high-pressure applications.

There are also different coatings available. Some pipes have a light coating for basic use, while others have heavier coatings for more demanding environments.

Consider your project's specific needs. Are you working on plumbing or construction?

Each use can determine the type you need. Think about how the pipe will interact with various substances. This reflection can save material costs and improve safety.

Always check local codes; they can guide your decisions.

When selecting the right galvanized pipe, understanding pipe sizes and schedules is crucial. Pipe sizes are typically designated by nominal diameter, which may differ from actual measurements. For instance, a nominal 1-inch pipe often has an outer diameter of 1.315 inches. This detail can impact your project substantially, especially when fitting connections or considering flow rates.

Pipe schedules further define wall thickness and strength. Common schedules are 40 and 80, where Schedule 40 is standard for most residential applications. It has a wall thickness that can sustain varying pressures, while Schedule 80 is thicker and better suited for high-pressure systems. According to industry reports, using the appropriate schedule can enhance durability and lifespan, reducing the need for future replacements.

Many projects fail due to poor material selection. It's essential to consider how external factors, like corrosion, may affect your choice. Galvanized pipes offer some protection but are not immune to rust over time. A failure to match pipe sizes and schedules to your specific needs can lead to costly repairs. Always double-check specifications and think critically about your project requirements before making a decision.

This chart illustrates the common sizes of galvanized pipes and their typical applications. Understanding these dimensions can help you select the right pipe for your project, ensuring proper fit and functionality.

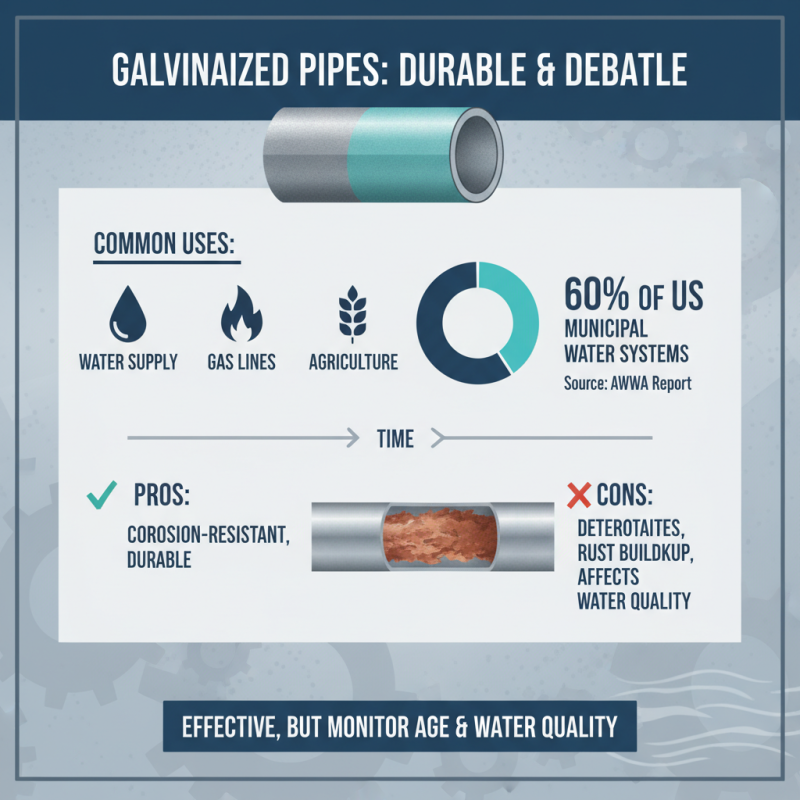

Galvanized pipes are widely used for various applications due to their durability and resistance to corrosion. They are commonly found in water supply systems, gas lines, and even in agricultural settings. According to a report from the American Water Works Association, approximately 60% of municipal water systems still utilize galvanized piping. However, it's essential to know that while galvanized pipes are effective, they can deteriorate over time due to rust buildup, affecting water quality.

In construction and plumbing, galvanized pipes serve as a reliable choice. For instance, they are ideal for frameworks and scaffolding. A study by ASTM International highlights that galvanized steel maintains its integrity even in adverse weather conditions. This makes it suitable for both indoor and outdoor applications. However, users should consider the potential for zinc coating to wear off, leading to premature failure. Local building codes may impose certain regulations that could render galvanized pipes inadequate for specific projects.

For agricultural use, galvanized pipes are often employed for irrigation systems. They resist moisture, but they aren't entirely immune to corrosion. As a result, regular inspection is necessary to avoid potential leaks or failures. It’s essential to weigh the pros and cons based on the intended application. Ultimately, informed decisions on galvanized pipe usage can lead to better project outcomes.

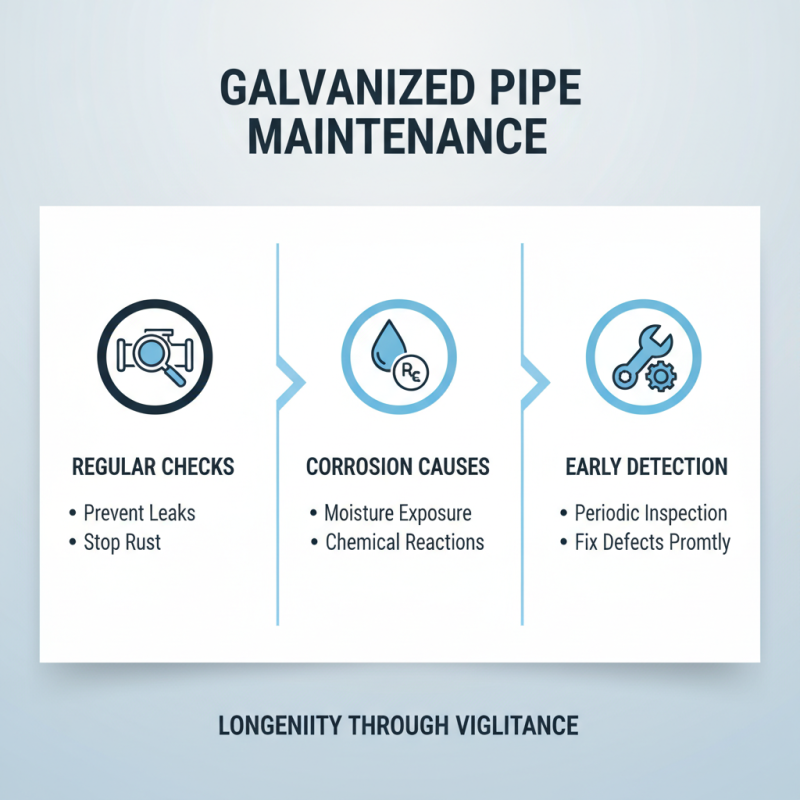

Maintaining galvanized pipes is essential for their longevity. Regular checks can prevent leaks and rust. These pipes can corrode over time due to moisture and chemicals. Inspecting your pipes periodically helps catch defects early.

One tip is to regularly check for visible signs of rust. Look for discoloration, especially around fittings. This can indicate a potential problem. Additionally, ensure that your pipes are properly insulated. Insulation helps reduce condensation. This minimizes the chances of rust forming on the surface.

It’s also important to avoid using harsh chemicals for cleaning. They can damage the protective zinc coating. Instead, use mild soap and water. Wipe down the exposed areas regularly. Dry them thoroughly afterward. Taking these basic steps can make a significant difference in the lifespan of your galvanized pipes.