As we look forward to the construction landscape of 2026, one material stands out: Hot Rolled Steel Coils. Known for their strength and versatility, these coils are essential in various applications. Industry expert Dr. Emily Carter emphasizes, "The quality of Hot Rolled Steel Coils shapes the future of construction." Her insight highlights the need for high standards in this critical material.

Hot Rolled Steel Coils are used in structural frameworks, bridges, and more. Their characteristics help builders achieve durability and efficiency. However, not all coils meet the required specifications. As demand rises, scrutiny over production processes is crucial. Ensuring quality not only affects projects but also the safety of structures.

Navigating the market in 2026 poses challenges. With numerous suppliers, distinguishing between quality and subpar coils becomes a daunting task. It's necessary to prioritize reliable sources. Construction professionals must engage with manufacturers who uphold rigorous testing standards. In this evolving landscape, commitment to quality is non-negotiable for future success.

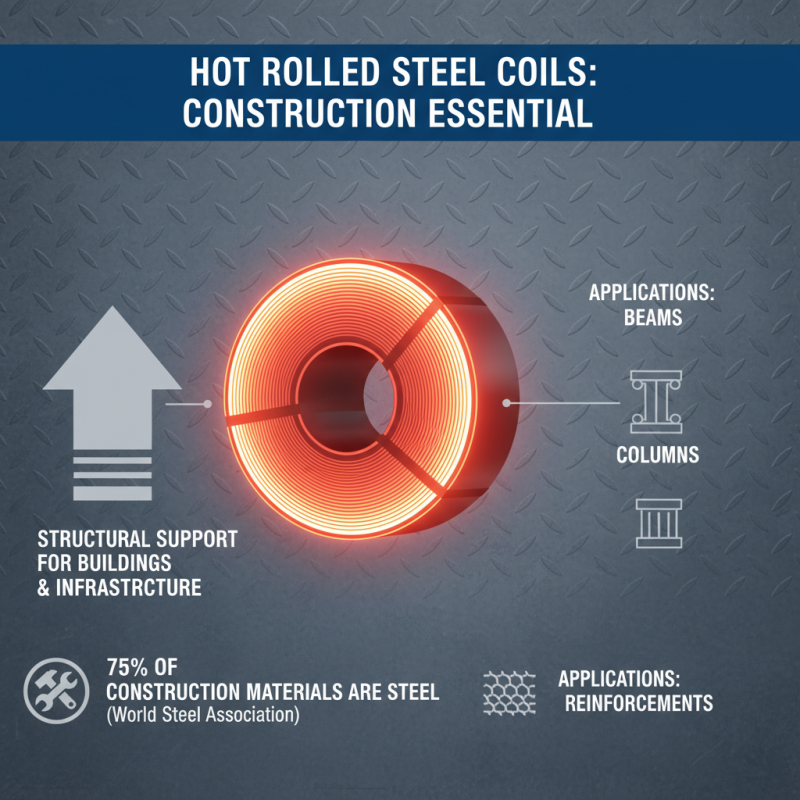

Hot rolled steel coils are vital in construction. They provide essential structural support for buildings and infrastructure. According to the World Steel Association, steel accounts for about 75% of the total material used in construction. This makes hot rolled steel coils a popular choice for various applications, including beams, columns, and reinforcements.

The production of hot rolled steel coils involves heating the metal above its re-crystallization temperature. This process enhances workability and ensures better mechanical properties. However, there are concerns. Inconsistent quality control can lead to defects, impacting structural integrity. Reports indicate that up to 10% of coils may fail quality tests, highlighting the need for strict inspections.

Hot rolled steel coils also offer cost advantages. They are typically cheaper to produce than cold rolled steel. The U.S. Geological Survey reported that the average price of hot rolled steel in 2021 was about $1,400 per ton. Yet, fluctuating global demand can drive prices up unexpectedly. Construction companies must stay informed to navigate these challenges effectively.

When choosing the best hot rolled steel coils for construction in 2026, several key features become crucial. First, consider the coil thickness. Industry standards suggest that thicknesses ranging from 1.5mm to 25mm are ideal for most applications. Thicker coils provide better strength but may require specialized processing for precision. A report by the World Steel Association highlights that steel demand will grow, emphasizing the importance of selecting the right material.

Another essential factor is the yield strength. High yield strength ensures robust structural integrity. A yield strength of at least 250 MPa is commonly preferred. Additionally, check the manufacturer's compliance with international standards, as this affects safety and performance.

Tips: Always inspect for surface defects. Even minor imperfections can lead to structural failures.

Finally, consider the coating of the steel. Anti-corrosive treatments can significantly enhance longevity. Reports indicate that investing in quality coatings can extend the lifespan by up to 50%.

Tips: Review specifications carefully. Small details matter a lot in construction.

In 2026, the demand for hot rolled steel coils in construction will likely be significant. Various manufacturers are investing in advanced technology. This enhances the production process and improves quality. The market is competitive. Selecting the best materials matters.

When choosing a manufacturer, consider their track record. A company’s history can indicate reliability. Look for feedback from past customers. This helps gauge performance and quality. Additionally, check their compliance with industry standards. Not all manufacturers adhere to these.

Tips for sourcing hot rolled steel coils: Always compare prices and quality. Don’t rush your decisions. Sometimes, the lowest price may not deliver the best value. Inspect the steel coils physically if possible. Be wary of suppliers without transparency. Small flaws in production could compromise your project.

| Specification | Thickness (mm) | Width (mm) | Length (mm) | Weight per Unit (kg/m) | Production Capacity (Tons/Year) |

|---|---|---|---|---|---|

| HR Steel Coil 1 | 3.0 | 1000 | 6000 | 7.85 | 50000 |

| HR Steel Coil 2 | 5.0 | 1250 | 8000 | 9.60 | 75000 |

| HR Steel Coil 3 | 4.0 | 1500 | 12000 | 8.00 | 60000 |

| HR Steel Coil 4 | 6.0 | 2000 | 10000 | 10.20 | 55000 |

| HR Steel Coil 5 | 2.5 | 800 | 5000 | 6.13 | 40000 |

Hot rolled steel coils are pivotal in construction, offering specific advantages over other types of steel. Their flexibility makes them ideal for structural applications. These coils are produced at high temperatures, allowing them to be easily shaped and formed. This process enhances their mechanical properties. However, they do have limitations. For instance, they can be more prone to surface defects.

In contrast, cold rolled steel coils provide a smoother finish and tighter tolerances, suitable for applications requiring precision. Yet, they lack the ease of shaping found in hot rolled steel. Another option is galvanized steel, which is coated for rust resistance. This adds extra protection but can increase costs. Each steel type has its unique benefits and drawbacks. Users must carefully evaluate their specific needs before making a decision.

All these factors play a role in the construction industry. The choice among hot rolled steel coils, cold rolled options, or galvanized varieties can greatly affect project outcomes. It’s vital to reflect on the specific requirements of your construction project. The ideal steel type may vary based on factors like budget and structural demands.

The construction industry is undergoing significant changes. Hot rolled steel coils are becoming increasingly essential. According to a recent industry report, the demand for these materials is projected to rise by 5% annually through 2026. This growth is largely driven by urbanization and infrastructure development.

Production methods are evolving. Many manufacturers are adopting more sustainable practices. For instance, the use of electric arc furnaces is on the rise. This method reduces carbon emissions significantly. Yet, challenges remain. The supply chain issues and fluctuating raw material prices may impact the availability of quality hot rolled steel.

Quality control is another area of concern. Ensuring the right specifications can be complicated. Not all producers meet the required standards. According to experts, about 20% of hot rolled steel coils fail to adhere to industry norms. This inconsistency can lead to structural failures. Stakeholders need to address these issues to ensure safety and reliability in construction projects.

This chart represents the projected production volume of hot rolled steel coils for the year 2026, segmented by quarters. It is anticipated that production will steadily increase throughout the year, reflecting the growing demand in the construction industry.