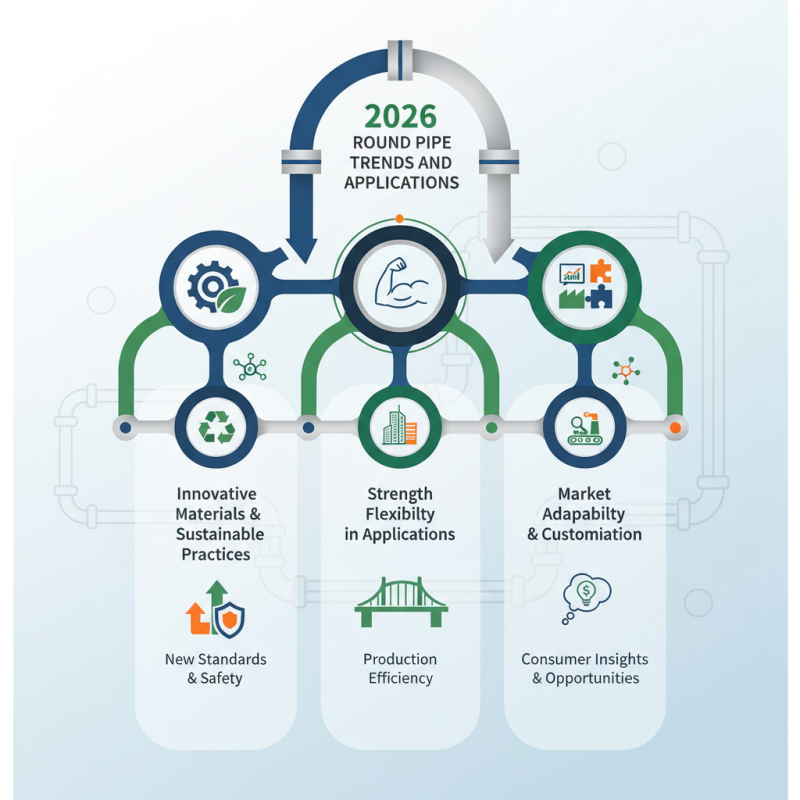

In the evolving landscape of construction and manufacturing, 2026 will showcase pivotal trends in the Round Pipe industry. Renowned expert John Doe stated, “Round pipes are the backbone of modern infrastructure.” This highlights their significance in various applications, from plumbing to structural components.

As technology advances, innovative materials and designs will emerge. Round pipes are increasingly favored for their strength and flexibility. Industries will integrate sustainable practices, focusing on recycled materials. However, the shift may pose challenges. Companies must adapt to new standards while ensuring safety and efficiency in production.

Moreover, understanding market demands is crucial. There’s a growing need for customized solutions. Yet, companies often overlook the importance of consumer insights. This oversight can lead to missed opportunities in a competitive market. The Round Pipe sector must prioritize adaptability and responsiveness to thrive in the coming years.

The round pipe industry is evolving rapidly. Innovations in materials and production methods are changing the landscape. For instance, lightweight composite materials are gaining traction. They provide durability and flexibility that traditional metals lack. This shift is crucial for applications in construction and automotive sectors.

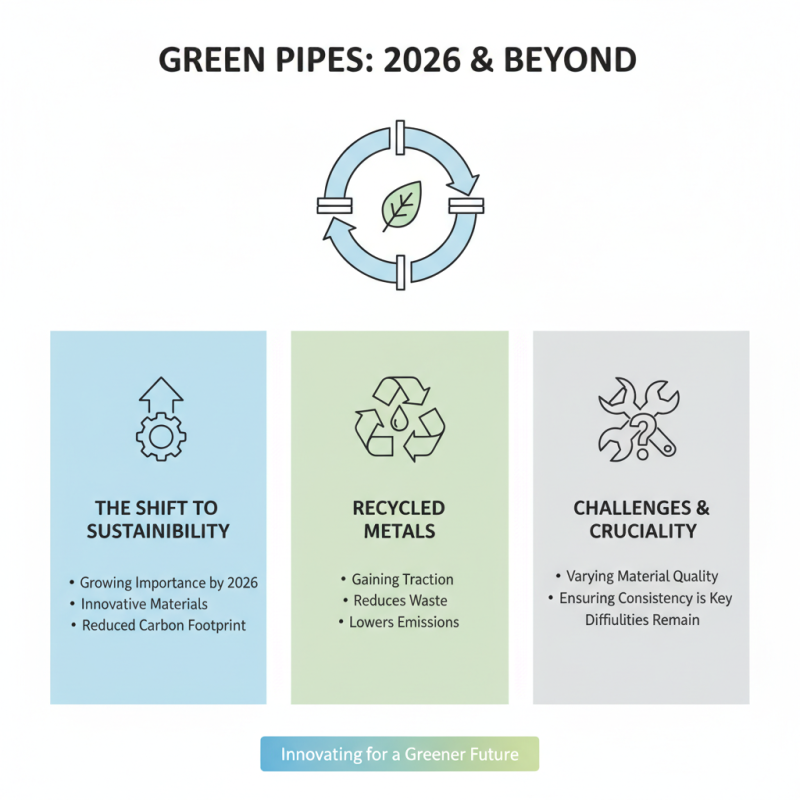

Sustainability is another vital trend. Many manufacturers are focusing on eco-friendly materials. These options reduce environmental impact while maintaining performance. Moreover, advanced recycling techniques are being implemented. Yet, questions arise about the efficacy and scalability of these techniques.

Technological advancements in pipe manufacturing are noteworthy. Automation and smart technologies help streamline production processes. These improvements can lead to reduced costs and increased precision. However, reliance on technology may pose challenges. Skilled labor is essential, and its scarcity could hinder growth. Balancing automation with human expertise remains a critical concern.

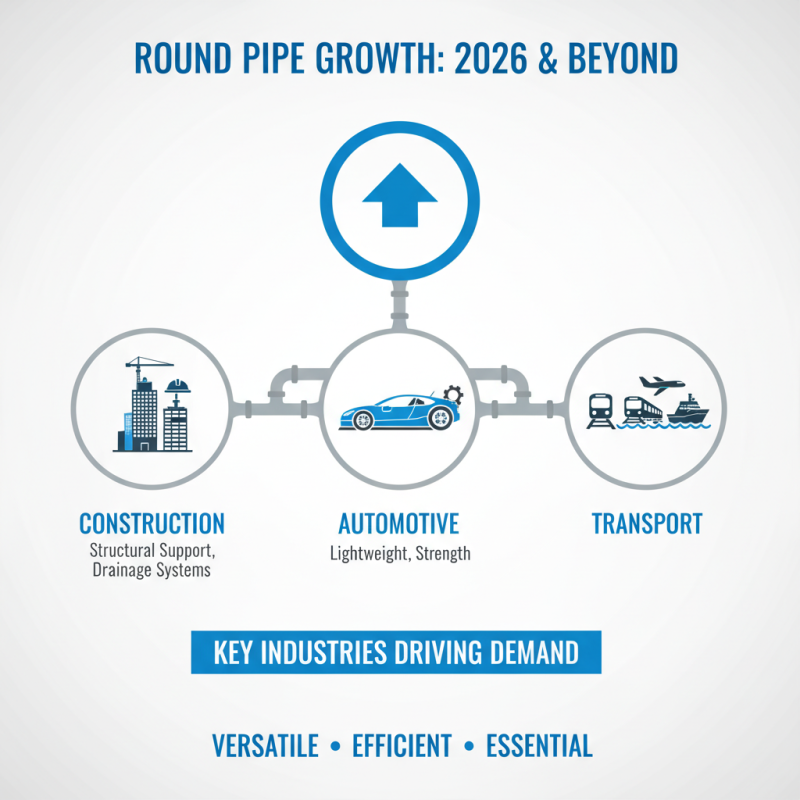

In 2026, the use of round pipes will see significant growth across various industries. These pipes are essential in construction, automotive, and transport sectors. For example, construction projects often use them for structural support and drainage systems. Similarly, automotive manufacturers employ round pipes for their lightweight and strength advantages.

Pipes are increasingly made from innovative materials. This innovation impacts how they are used. In energy sectors, for instance, round pipes are pivotal in oil and gas transportation. Their durability allows them to withstand tough conditions. Yet, industry professionals must address potential durability concerns. It’s crucial to assess if these new materials meet industry standards over time.

Tips: Always consider the pipe's corrosion resistance when selecting materials. Look for options that promise better longevity. Additionally, think about the maintenance costs associated with different pipe types. Choosing the right round pipe can result in long-term savings and increased efficiency.

As we move toward 2026, sustainability in round pipe production is becoming increasingly important. Manufacturers are exploring innovative materials. For instance, using recycled metals is gaining traction. This method reduces waste and lowers carbon footprints. Still, it is not without its challenges. The quality of recycled materials can vary significantly. Ensuring consistency is crucial yet difficult.

Another trend is energy-efficient production methods. Factories are now adopting renewable energy sources. Solar and wind power are becoming more common. However, transitioning to these methods requires time and investment. Many producers may hesitate due to initial costs. It's a balancing act between immediate expenses and long-term savings.

Finally, circular economy principles are shaping future production. Companies are designing products with end-of-life in mind. This means easier recycling or reusability. Yet, implementation remains inconsistent across the industry. Some firms still prioritize short-term profits over sustainable practices. The path to greener production is fraught with obstacles, but it’s a necessary journey.

In 2026, round pipe performance is undergoing a transformation. New materials are being developed that enhance durability. These advances allow pipes to resist corrosion better than ever before. Additionally, lighter materials contribute to easier handling during installation. It is essential to recognize that not all innovations are universally applicable. Some materials may not perform well in extreme conditions.

Advances in manufacturing techniques also play a crucial role. Techniques like 3D printing support customized pipe designs. This means better fit and increased efficiency in installations. However, the reliability of these methods needs thorough testing. As technology evolves, some traditional methods may struggle to adapt. This can lead to unexpected challenges in integration.

Moreover, smart technologies are becoming essential in pipe systems. Sensors can now monitor pressure and flow in real-time. This integration helps in detecting leaks quickly, which is vital for maintenance. Yet, the reliance on smart technology poses questions about data security. Potential vulnerabilities could lead to significant risks. Balancing innovation with reliability remains a challenge for the industry.

| Trend/Application | Description | Technological Advancement | Impact on Performance |

|---|---|---|---|

| Lightweight Materials | Use of advanced alloys and composites to reduce weight. | Development of new material compositions. | Increases ease of installation and transportation. |

| Smart Pipe Technology | Integration of sensors for real-time monitoring. | Advancements in IoT and sensor technology. | Enhances safety and maintenance efficiency. |

| Corrosion Resistance | Pipes designed to withstand harsh environments. | New coating technologies and surface treatments. | Lowers maintenance costs and extends lifespan. |

| Sustainable Production Techniques | Eco-friendly manufacturing processes. | Innovations in recycling and waste reduction. | Reduces environmental impact and promotes sustainability. |

| High-Pressure Applications | Pipes designed for extreme pressure conditions. | Improved engineering and simulation technologies. | Increases safety and reliability in critical systems. |

The round pipe market is evolving rapidly. By 2026, growth is expected to surge due to increased construction and manufacturing demands. In major industries, round pipes are crucial for efficient fluid transport and structural integrity. The versatility of materials, like steel and plastic, enhances their application across sectors.

However, challenges remain. Environmental regulations are becoming stricter, forcing manufacturers to adapt. Sustainability is now a priority, impacting production methods. Companies need to invest in eco-friendly technologies. This shift can strain budgets and resources. Adapting to these regulations requires innovation and flexibility, which not all companies can achieve easily.

Market analysis shows fluctuating raw material costs. This uncertainty influences pricing strategies. Manufacturers must navigate these financial hurdles carefully. Furthermore, competition is intensifying, creating a need for differentiation. Companies often struggle to balance quality and cost. Many are still figuring out the best solutions for these emerging challenges.

This bar chart illustrates the projected growth rates of the round pipe market from 2022 to 2026. As per the analysis, a steady increase in market growth is expected, reaching up to 20% by 2026.