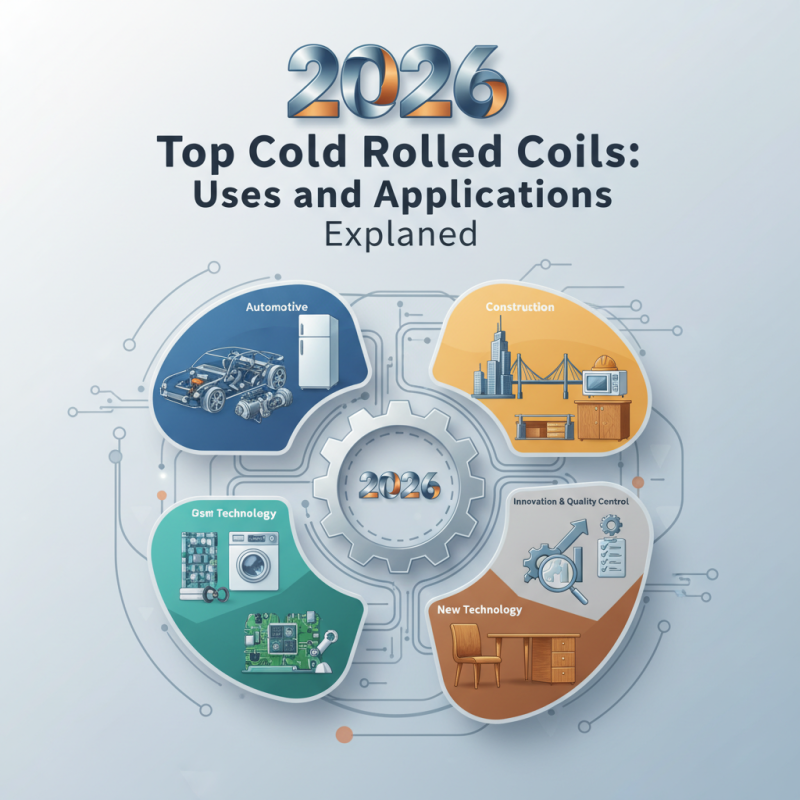

Cold Rolled Coils are essential in various industries today. These coils are widely used due to their unique properties and versatility. They offer a smooth surface, high strength, and excellent formability. This makes them ideal for a range of applications, from automotive parts to appliances.

In 2026, the demand for Cold Rolled Coils will likely increase. Industries are adapting to new technologies and trends. This creates exciting opportunities for manufacturers. However, challenges remain in quality control and production efficiency. Companies must innovate and improve processes to meet customer needs.

Understanding the applications of Cold Rolled Coils can provide valuable insights. They play a significant role in construction, furniture, and more. Each industry uses them differently. Yet, the pursuit of perfection can sometimes lead to oversights. It is vital to reflect on potential improvements continuously.

Cold rolled coils are widely used in various industries. They are produced through a specific manufacturing process that enhances the strength and surface finish of the steel. The journey begins with hot rolled steel. This material undergoes cooling and further processing to achieve the desired dimensions.

During the cold rolling process, the steel is passed through rollers at room temperature. This reduces thickness and improves the surface quality. The final product has a smooth finish and is easier to work with. Cold rolled coils find applications in automotive parts, appliances, and construction materials.

Tip: Invest in quality tools when working with cold rolled coils. It makes a noticeable difference.

Cold rolled coils can also be prone to defects, such as warping or surface blemishes. This can affect their usability. So, proper handling is crucial.

Tip: Always check for imperfections before using the coils. It saves time in the long run.

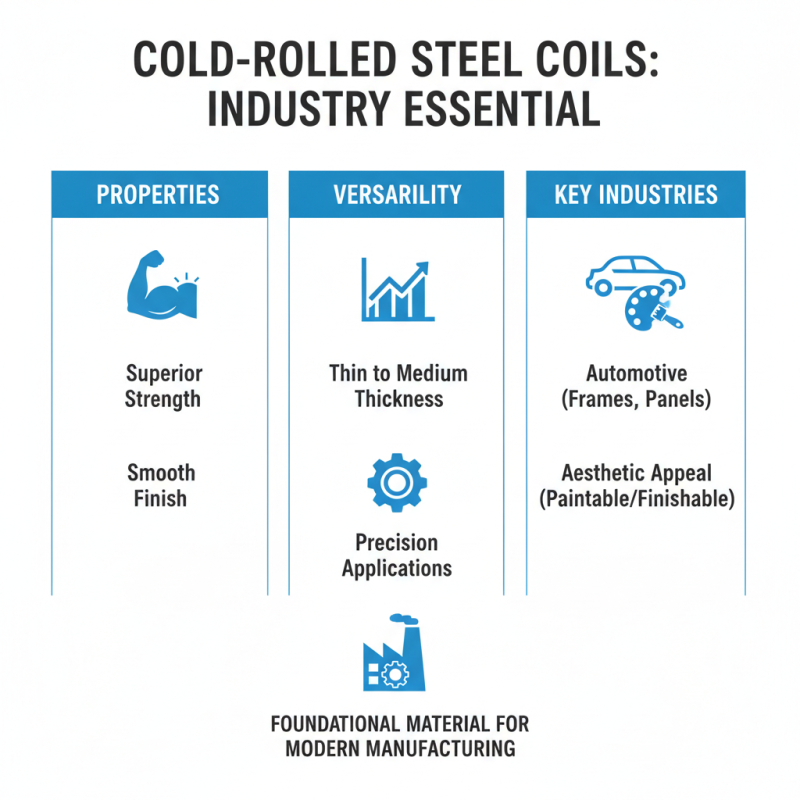

Cold rolled coils are vital in various industries due to their unique properties. These coils possess superior strength and a smooth finish. This makes them suitable for applications requiring precision. Their thickness ranges from thin to medium, making them versatile for multiple uses. Specifically, they are often used in the automotive sector for parts like frames and body panels. The aesthetic appeal of cold rolled steel is another significant advantage. It can be easily painted or finished to meet design specifications.

Another important property is their excellent surface quality. This quality aids in reducing the need for additional treatments. Manufacturers appreciate that cold rolled coils can be easily formed into intricate shapes. However, there are challenges. The production process can lead to defects, requiring thorough inspections. Many companies find it hard to achieve consistency in quality. This can impact the final product. Industries often need to rethink their methods to ensure they meet high standards.

Moreover, cold rolled coils exhibit good machinability. They are easy to weld and cut, making them efficient for production. However, using these coils can be a double-edged sword. If not handled properly, they can lead to increased waste. Decision-makers must weigh the benefits against potential drawbacks. Investing in quality control is vital for minimizing risks. Embracing improvement can enhance the overall functionality of cold rolled products.

In automotive manufacturing, cold rolled coils play a crucial role. These coils are known for their superior surface finish and precise dimensions. They provide excellent strength, making them ideal for various components. For example, they are often used in body panels and structural parts. Industry reports indicate that the cold rolled steel market is expected to grow significantly by 2026, driven by increasing automotive production.

One interesting application of cold rolled coils is in safety features. They can be found in crumple zones and reinforcements, which help absorb impact during collisions. This enhances vehicle safety, a crucial selling point for consumers. Data shows that vehicles with high-strength cold rolled steel components have improved crash test ratings.

**Tip:** Always consider the thickness of the coils. Thicker materials offer better durability but may increase vehicle weight. Striking a balance is essential for fuel efficiency.

Another aspect to note is the surface treatment process. Cold rolled coils often undergo coatings to resist corrosion. However, not all treatments are created equal. Some may not provide sufficient protection over time. It’s important to assess these factors during material selection.

**Tip:** Regularly review industry standards. Changes may impact your manufacturing processes or material choice. Staying informed is crucial for maintaining quality and competitiveness.

| Application Area | Description | Advantages | Common Thickness Range (mm) |

|---|---|---|---|

| Automotive Body Panels | Used in manufacturing doors, hoods, and trunks for vehicles. | Lightweight, good surface finish, high strength. | 0.4 - 2.0 |

| Chassis Components | Structural parts providing support and rigidity to vehicles. | High tensile strength, durability, cost-effective. | 1.0 - 3.0 |

| Interior Trim | Used for dashboards, instrument panels, and door frames. | Aesthetic appeal, versatility in design, lightweight. | 0.5 - 1.5 |

| Suspension Systems | Components such as springs and mounts for vehicle stability. | Enhanced performance, high-load bearing capacity. | 1.5 - 4.5 |

| Engines | Used in engine blocks, crankshafts, and other components. | Corrosion resistance, high thermal conductivity. | 2.0 - 5.0 |

Cold rolled coils play a crucial role in construction and building materials. These steel products have superior surface quality and precise dimensions. According to industry reports, the demand for cold rolled steel in construction has increased by 15% over the last five years. Builders prefer cold rolled coils because they enhance strength and durability in structures.

Different applications benefit from the unique characteristics of cold rolled coils. For example, they are used in the fabrication of roofing sheets, wall panels, and structural components. A notable statistic reveals that around 30% of cold rolled steel is used in residential and commercial building applications. However, sourcing high-quality coils can be a challenge. Variability in the production process often leads to inconsistencies, which require careful inspection.

The aesthetic appeal of cold rolled coils cannot be overlooked. Their smooth finish allows for varied architectural designs. Yet, one should question whether the industry emphasizes the environmental impact of production. As construction continues to grow, balancing quality and sustainability remains a critical issue. The ongoing reliance on cold rolled coils demands attention to both their benefits and potential drawbacks.

Cold rolled coils are witnessing significant evolution. In 2026, their applications span various industries. Automotive manufacturing remains a key area. The design of vehicles now prioritizes lightweight materials for better efficiency. Cold rolled coils provide strength without adding excess weight. This shift is reshaping vehicle design.

In construction, these coils offer a competitive advantage. Architects appreciate their versatility and durability. With urbanization on the rise, the demand for high-quality materials increases. Cold rolled coils will likely find uses in innovative building components. The trend towards sustainability is also notable. Incorporating recycled materials into cold rolled coils could be a game changer. However, challenges exist in maintaining quality while reducing environmental impact.

The packaging industry is embracing cold rolled coils too. Aesthetics and sturdiness make them ideal for modern packaging solutions. Some industries may struggle with adaptation. There’s a gap between traditional practices and new technologies. Adjusting production processes may prove difficult. As the landscape shifts, staying ahead requires constant innovation and reflection.